What is the Principle of Thermogravimetric Analysis?

Thermogravimetric analysis is extremely useful for administering quality control and ensuring that various industries, such as chemical, pharmaceutical, petroleum and polymer manufacturers, can comply with different safety procedures.

We can learn a lot about a material through thermogravimetric analysis. This includes its structure, purity and how quickly it dries, combusts or decomposes. It also examines how well a material can absorb liquid or remain stable under different levels of heat. Find out more about it below.

Fundamentals of Thermogravimetric Analysis

At its core, thermogravimetric analysis measures the mass of a sample as it is:

- Heated

- Cooled

- Held at a constant temperature.

The primary output is a thermogram. A thermogram’s plot represents the relationship between the mass of a sample and temperature or time.

Through this analysis, one can deduce critical information about a material’s:

- Thermal stability

- Decomposition temperatures

- Absorbed moisture content.

It can also detect the presence of various components such as fillers, reinforcements, and plasticizers in polymers.

The Principle of Operation

The principle of operation of thermogravimetric analysis is straightforward yet powerful. A sample is placed in a small pan or crucible, which is then positioned in a furnace with a precisely controlled temperature program. The sample is then subjected to a controlled temperature regime. This typically involves heating at a constant rate, although isothermal (constant temperature) conditions can also be applied.

During the heating process, changes in the mass of the sample are continuously recorded by a highly sensitive balance. These mass changes are related to various physical and chemical processes such as:

- Dehydration

- Decomposition

- Oxidation.

Key Components of Thermogravimetric Analysis

- Balance System: The heart of the thermogravimetric analysis instrument is a high-precision balance capable of detecting minute changes in mass (in the microgram or even nanogram range).

- Furnace: Its furnace is capable of reaching high temperatures (often up to 1000°C or higher). This controlled heating rate is essential for the thermal treatment of the sample.

- Temperature Control: Precise temperature control is vital for accurate thermogravimetric analysis measurements. It includes not only the heating rate but also atmosphere control (inert, oxidative, or reducing atmospheres can be used depending on the application).

- Data Acquisition and Analysis Software: Modern thermogravimetric analysis instruments are equipped with sophisticated software for data recording, analysis, and the interpretation of results.

Applications of Thermogravimetric Analysis

Thermogravimetric analysis has a broad range of applications across various fields because of its ability to provide detailed information about material properties. Some of the key applications include:

- Material Characterization: Determining the composition of complex materials, including polymers, composites, and pharmaceuticals, by identifying their components based on their thermal decomposition profiles.

- Thermal Stability: Evaluating the thermal stability of materials is crucial for applications where materials are subjected to high temperatures.

- Lifetime Prediction: By analyzing the kinetics of decomposition, thermogravimetric analysis can help predict the lifetime of materials under specific thermal conditions.

- Moisture and Volatile Content Analysis: Thermogravimetric analysis is highly effective in measuring the moisture and volatile content in materials. This is crucial for many industrial processes.

Advantages and Limitations

Advantages

- Versatility: This tool can analyze a wide range of materials, including polymers, metals, ceramics, and composites.

- Quantitative Analysis: It provides quantitative data on the composition and thermal stability of materials.

- High Sensitivity: Thermogravimetric analysis can detect small changes in mass, making it suitable for analyzing minute samples.

Limitations

- Sample Size and Homogeneity: The technique requires a representative sample that is small yet homogenous.

- Interpretation of Results: The interpretation of thermogravimetric analysis data can be complex, especially when dealing with materials that undergo multiple simultaneous or overlapping processes.

- Atmosphere Control: The results can be significantly influenced by the atmosphere in the furnace. Therefore, careful selection and control of the gas environment is required.

The Principles of Thermogravimetric Analysis Make It a Key Tool With a Variety of Applications

It is only by using thermogravimetric analysis principles that we can learn more about a material’s reactivity. This includes how the energy of its molecules can impact its physical properties.

As the future draws ever nearer, thermogravimetric analysis tools, like thermogravimetric analyzers, will continue to be enhanced. This includes automating thermogravimetric analysis technology to make devices more efficient.

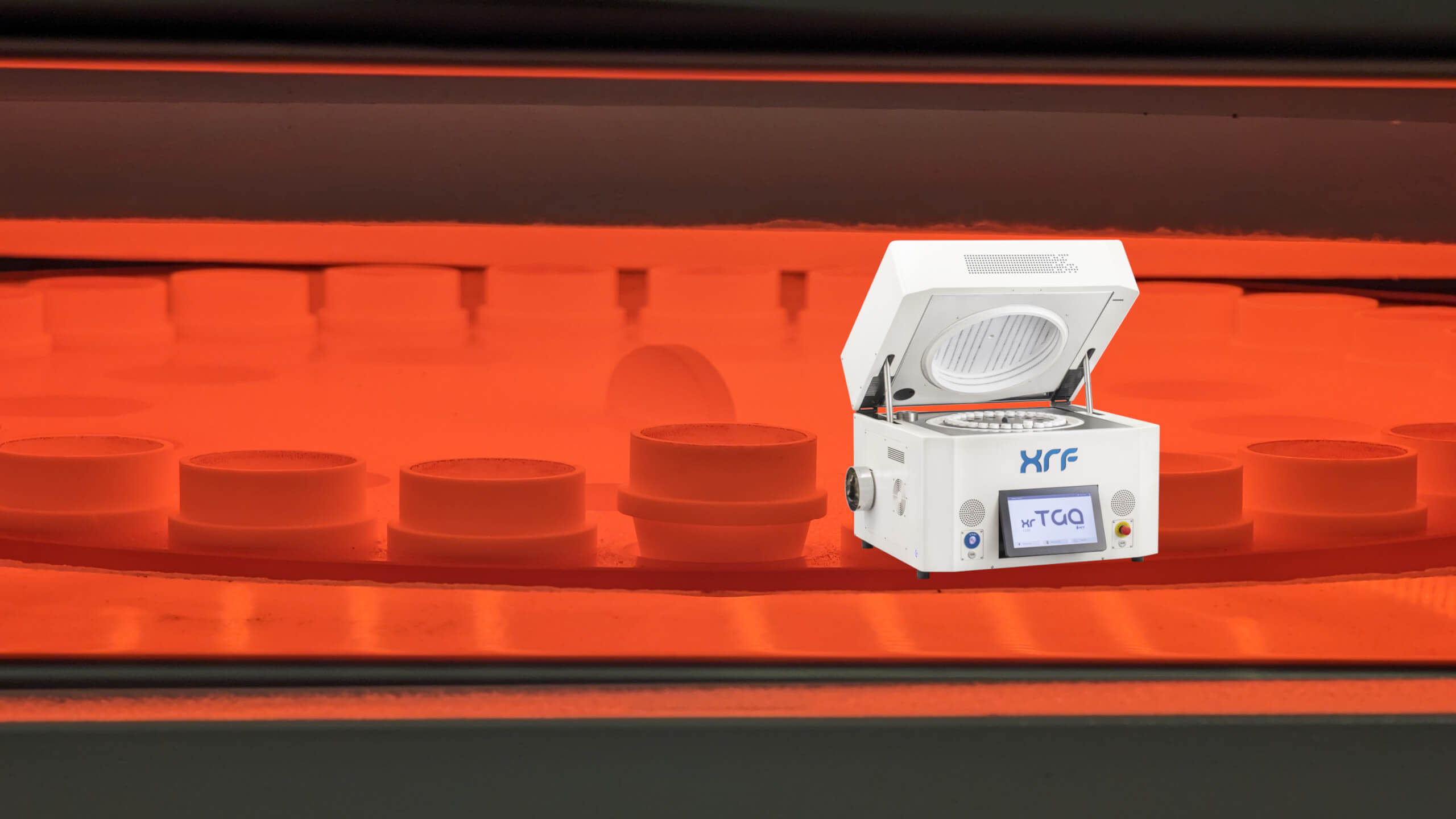

Whether you are applying thermogravimetric analysis to meet quality control standards in your industry, or you simply want to learn more about what is the principle of thermogravimetric analysis, we, XRF Scientific, can help you find the perfect thermogravimetric analysis solution for your work.

As a starting point, we would recommend considering our XRTGA-1100! This thermogravimetric analyzer can be used with a number of materials. It has an enhanced system that is simple to operate and can offer quick temperature variations. Not only that, but it has a carousel for 30 samples, which is perfect for use in a fast-paced laboratory.

Our thermogravimetric analyzers represent innovation at its finest. For more information about them, please feel free to contact us.