Our Technology

Sample Preparation Products

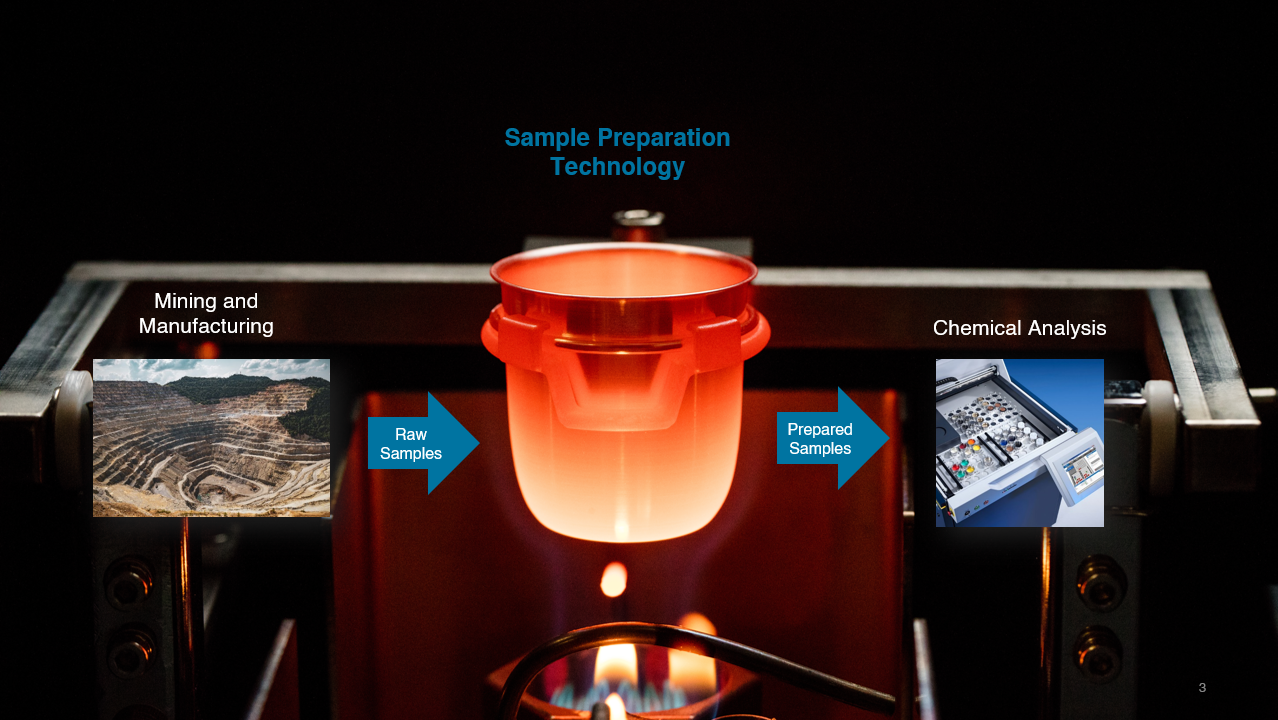

XRF Scientific provides technology for sample preparation in the fields of XRF and ICP analysis.

A typical work flow in an XRF laboratory is as follows:

1. Samples are generated through drilling at a mine (iron ore, base metals) or from a production plant (cement, steel etc.)

2. The samples are crushed and pulverised into a fine dust

3. Samples (typically 1gm) are weighed accurately into an XRF Scientific platinum crucible

4. The XRF Scientific flux reagent (typically 10gm) is weighed and then put into the platinum crucible

5. The sample and flux are fused together at high temperatures using an XRF Scientific electric or gas fusion machine

6. The machine automatically pours the molten mixture into an XRF Scientific platinum mould

7. The machine cools and sets the mixture into a glass disc

8. The glass disc is then put inside an XRF spectrometer and analysed for its chemical content

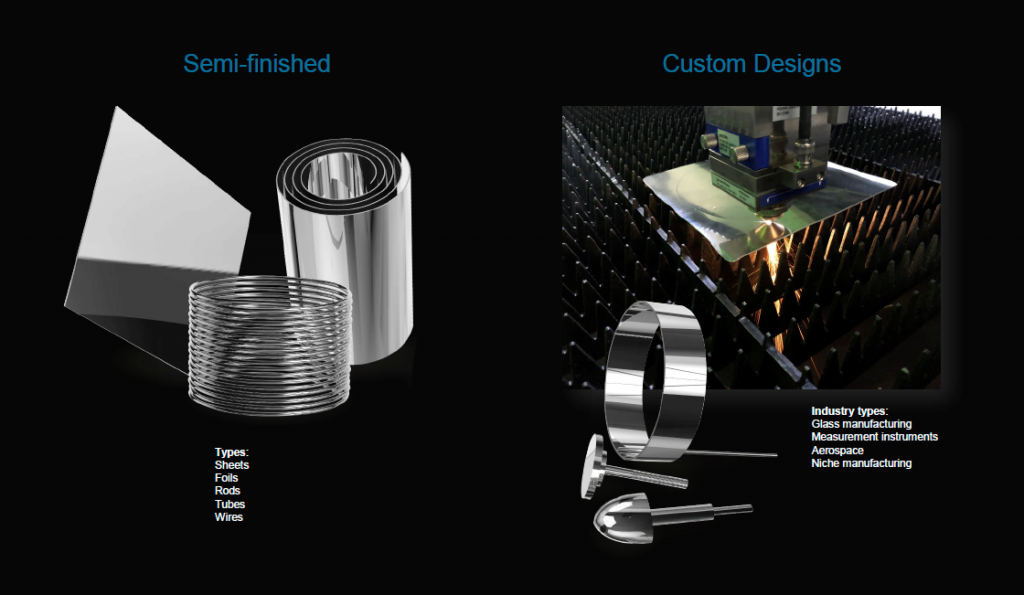

Precious Metals Products

Platinum’s high melting point, chemical inertness and workability during manufacturing make it an ideal choice across a number of different applications. We manufacture products for laboratories such as dishes and fusion labware. For industrial customers we manufacture semi-finished products including sheets, foils, wires, rods and tubes.

For unique applications our engineering and production teams work to solve individual customer problems and provide customised platinum components. Many of these platinum components are used in manufacturing processes such as the production of glasses or crystal growing for electronics. Smaller platinum components often form part of the assembly of a larger product such as an analytical measurement instrument.