How to Test for Ash Content in Plastics via TGA Analysis

When plastic is burned it produces ash content, an inorganic residue that contains parts of the material that have not been affected by the heat. These can include pigments, fillers, and reinforcements. Depending on what it contains, ash content can affect the characteristics of the plastic. If a plastic contains a filler, such as talc or calcium carbonate, it is likely that its thermal stability and stiffness will be increased. However, too much of a filler could lower its strength. By undertaking ash content analysis, there is the potential to understand what it contains and, thus, how its content could affect its overall properties. This knowledge can be applied to quality control measures to optimize plastics as they proceed through development. Not only can this ensure the completed plastic product will act as expected, but it can help to manage expenses associated with producing the plastic. Thermogravimetric analysis (TGA) is a technique used for testing plastics for their ash content. It analyzes changes in a material’s mass while the temperature is altered, providing information on any activities that could modify it. TGA analysis can be applied to plastic to ascertain its amount of weight loss when placed in a high temperature. From there, an understanding can be drawn about the levels of inorganic materials it contains. Read on to discover how to undertake TGA analysis to ascertain the ash content in plastics.

Step-by-Step Procedure

Sample Preparation

Begin by weighing a small sample of the plastic material in a tared TGA crucible. The sample should be between 10 to 50 mg. This small sample size is sufficient due to the sensitivity and precision of TGA analysis instruments. Accurate weighing is crucial to ensure the reliability of the results.

Initial Heating under Inert Atmosphere

Load the crucible into the TGA analysis instrument. After loading the device, set a temperature ramp under an inert atmosphere, such as nitrogen. The temperature should be programmed to increase to around 600-800°C. This step pyrolyzes the sample, removing all organic components through thermal decomposition without oxidation. The inert atmosphere prevents combustion, ensuring that only the organic parts are decomposed, leaving behind the inorganic residues.

Oxidative Atmosphere and Final Heating

After the pyrolysis phase, switch the atmosphere to oxidative (air or oxygen). Then increase the temperature, typically to about 800-1000°C. This stage fully oxidizes any remaining inorganic residue, converting it to ash. The oxidative environment ensures that all combustible components are burned off, leaving only the inorganic ash content.

Continuous Weight Measurement

Throughout the entire process, TGA analysis continuously measures and records the sample weight. The resulting thermogram plots weight changes against temperature or time. The final stable weight, reached after the oxidative heating, represents the inorganic ash content of the original plastic sample.

Key Considerations of TGA Analysis

Accuracy and Replicability

TGA analysis offers a fast and accurate measurement of the total inorganic filler or ash content in plastics. However, for enhanced accuracy, it is advisable to run multiple replicates of the sample. This approach helps mitigate any variability and ensures that the results are consistent and reliable.

Inability to Differentiate Inorganic Fillers

One limitation of TGA analysis is its inability to distinguish between different types of inorganic fillers. While TGA analysis provides the total inorganic content, it does not identify the specific types of fillers present. Visual examination of the ash residue post-analysis can offer some insights. This is because different fillers, such as glass fibers or mineral fillers, may have distinct appearances.

Standards and Protocols

Adherence to standardized protocols is crucial for reliable and reproducible results. TGA analysis ash testing follows standards, such as ASTM E1131 and ISO 11358. These provide guidelines for performing TGA analysis of plastics and polymers. Following these standards ensures that the TGA analysis is conducted under controlled conditions, delivering consistency across different laboratories and studies.

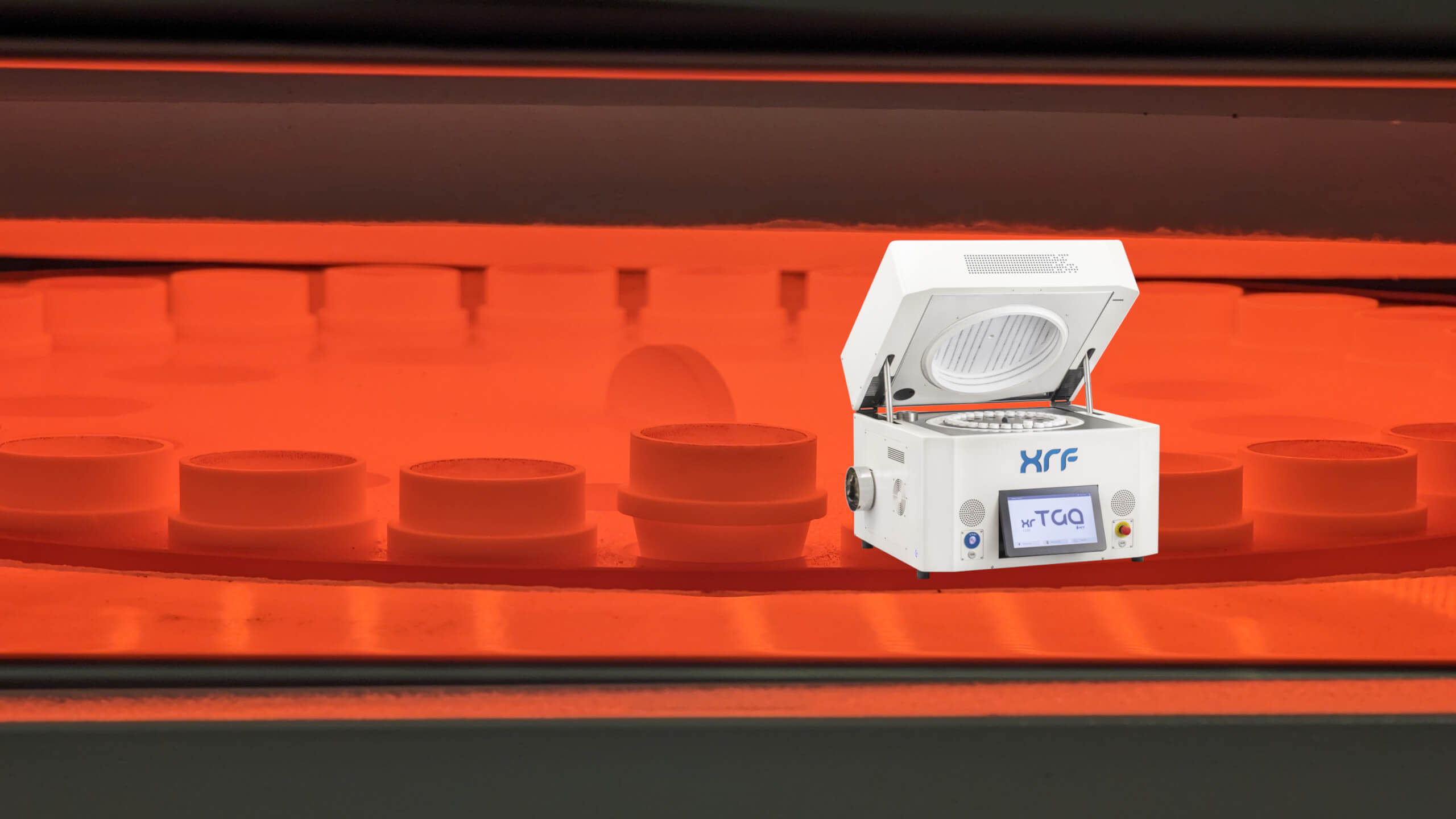

Apply TGA Analysis to Your Plastics With Equipment from XRF Scientific

TGA analysis is a robust technique for gathering insights about the inorganic materials that help to compose plastic. It can identify these components by examining their thermal stabilities and any reduction in the plastic’s overall weight when experiencing increased temperatures. Discover additional information about TGA analysis by reading our guide. When you are ready to utilize the capabilities of TGA analysis for examining plastics, we, XRF Scientific, would highly recommend going to our website to see our TGA analysis equipment. There you will find the xrTGA 1100, a thermogravimetric analyzer with an extensive throughput, thanks to its carousel that can hold 30 materials. It can also deliver temperatures that reach 1100°C for heating the sample and has extremely quick cooling and heating cycles. The right equipment can help you undertake TGA analysis with ease. Apply the xrTGA 1100 to your research and discover more about the properties of your plastics.