xrFuse 2: Fusion Instruments for XRF and ICP Specifications

Fusion instruments for analytical sample preparation are typically divided by their heating methods (i.e. gas or electric). Either technology can be used to prepare samples as homogenous glass beads for x-ray fluorescence (XRF) or as heterogeneous solutions for inductively-coupled plasma (ICP) analysis. In fact, the differences between gas and electric fusion are largely superficial. Fusion instruments should, therefore, be judged based on the individual merits of distinct products such as the fusion throughput, levels of automation, and its energy efficiency.

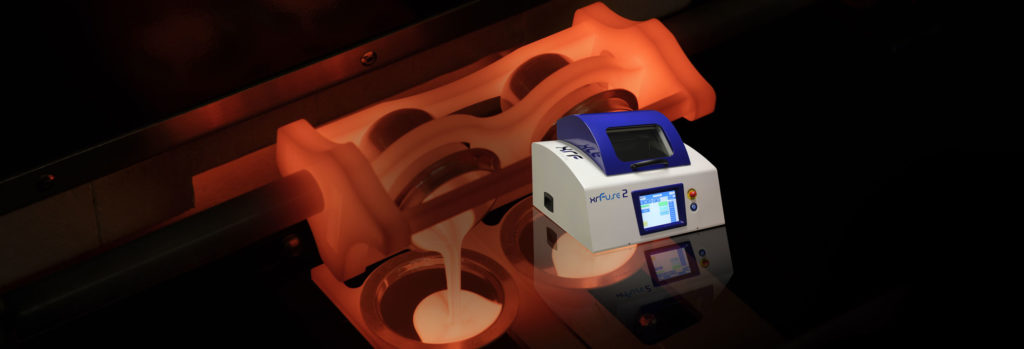

The xrFuse 2 belongs to our proprietary range of electric fusion instruments which is suitable for intermediate throughput XRF and ICP sample preparation. In this blog post, we will explore the specifications of the xrFuse 2 in more detail.

The Properties of the xrFuse 2

The xrFuse 2 is a high purity industrial furnace capable of rapidly escalating the temperature of its heating chamber to a peak of 1250°C (2192°F). These temperatures are generated by silicon carbide (SiC) heating rods as opposed to wire-wound or Molybdenum disilicide elements, due to the enhanced mechanical integrity of the ceramic overtime. This contributes to the improved service life of the fusion instrument.

XRF Scientific use high-performance ceramic materials throughout the interior of the xrFuse 2, from its heating rods to its high-purity ceramic cradle, which is proven to last as much as 5 times longer than an Inconel alternative. This component can facilitate molds of 23 – 40mm in diameter with a throughput of up to 10 samples per hour.

The exterior is comprised of a robust aluminum housing that has been optimized for safe operation using infrared monitoring technology. This ensures that the exterior of the fusion instrument is safe to touch throughout the entirety of its operating cycle. Even when the xrFuse 2 reaches maximum internal temperatures, the exterior shell will not exceed 50°C (122°F). A sturdy glass panel enables analysts to continuously view the fusion process, which is ideal for method development applications.

Applications of the xrFuse 2

The xrFuse 2 is a versatile fusion instrument optimized for both XRF and ICP sample preparation. It was optimized for high volume sample preparation of iron ore samples and has found wide success in the preparation of a broad range of mineral oxides for ultra-precise spectroscopic analysis. We recently reported on a successful method for preparing construction materials for analysis using the xrFuse 2.

Fusion Instruments from XRF Scientific

XRF Scientific is the world’s leading authority in XRF and ICP sample preparation, providing method development solutions and services alongside a robust range of flux products. We also supply an extensive range of fusion instruments suitable for sample preparation in the field or in larger throughput laboratory environments.

If you would like any more information about the xrFuse 2, or any of our other fusion instruments, simply contact us directly.