Essential Lab Equipment for XRF Analysis

X-ray fluorescence (XRF) is one of the only elemental analysis tools capable of identifying and quantifying the elements present in a bulk material non-destructively. This is conducted by extracting a small sample volume from the uppermost surface layers of the material or taking a fragment of the bulk product and homogenizing it as a fine powder. A benchtop XRF spectrometer is then used to measure the component parts of the sample and develop relative data for the bulk material. This requires several distinct pieces of lab equipment to achieve optimal results.

Alternative tools such as optical emission spectrometry (OES) and laser-induced breakdown spectrometry (LIBS) can perform elemental analysis of workpieces directly, without extensive sample preparation. However, these techniques offer limited analytical capabilities compared to benchtop XRF spectroscopy. They also tend to leave visible marring on workpieces which mitigates the benefits of being able to test materials without careful sample preparation using dedicated lab equipment.

The diligent use of lab equipment like platinum labware, high-performance fusion furnaces, and chemistry-specific molds facilitates the most accurate quantitative and qualitative analysis of samples in a non-destructive manner currently available. This blog post will explore the essential lab equipment for correct XRF sample preparation, alongside some additional accessories that can improve the accuracy of your results.

Platinum Moulds and Crucibles

Platinum lab equipment is foundational for XRF sample preparation best practice. At XRF Scientific, we have written at length about using a platinum crucible for sample fusion due to the material’s exceptional thermodynamic stability up to typical use temperatures of fusion furnaces (~1250°C). The geometry and alloying content of platinum lab equipment are application specific, with standard forms, Capsule-Kawin crucibles, and low profile designs available for varying sample types.

The most common platinum alloy for fusion applications is platinum-gold alloys at a ratio of 95—5%, platinum-rhodium-gold alloys are options for higher continuous temperature fusion.

Fusion Furnace Equipment

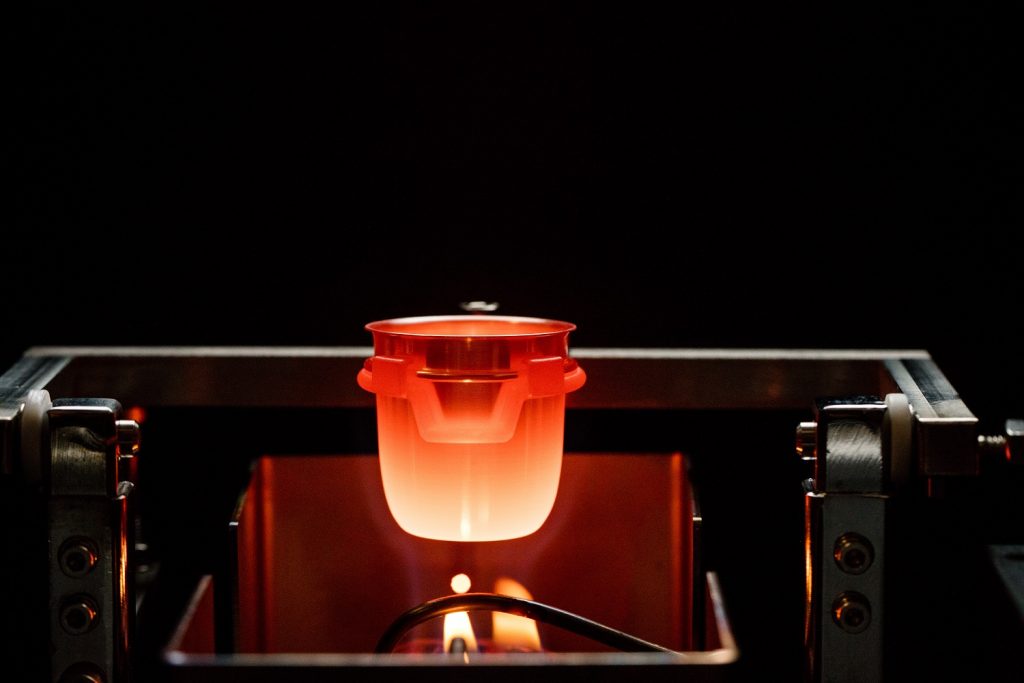

Once the homogenous sample material is loaded with an appropriate eutectic fusion flux mixture in a platinum crucible, it is loaded into the mantle of a fusion flux furnace. These are specialist pieces of lab equipment designed to house multiple crucibles in a functional mantle that will rock to mechanically agitate sample material simultaneously with heating.

This rocking motion serves the dual function of agitating sample material and eventually pouring the molten mixture into pre-loaded platinum molds. To guarantee that the homogenous sample disc or bead will remove successfully from the mold, samples may require additional release agents to be mixed into the eutectic flux.

More complex samples may require homogenization using a jaw crusher, and high throughput XRF analysis may utilize automatic weighing and dosing lab equipment to accelerate sample preparation. However, the only mandatory equipment required to prepare sample materials for XRF analysis is conventional platinum labware and a specialized fusion furnace.

Lab Equipment from XRF Scientific

XRF Scientific is one of the world’s leading suppliers of lab equipment for XRF and inductively-coupled plasma (ICP) spectroscopy sample preparation. If you would like any more information about the additional tools for higher volume XRF analysis, read our previous blog posts:

Otherwise, contact us directly if you have any questions.