How a Laboratory Crusher Works

A laboratory crusher, or pulverizer, is a device designed to forcefully reduce solid samples such as rocks to fine dust or powder for molecular analysis. It is a crucial process for XRF sample preparation of dry, organic samples as the particle sizes of substances must be reduced to micro scales for accurate XRF analysis to take place.

After a geological sample has been processed through a laboratory crusher it can be spectroscopically analyzed to determine various material properties of the sample, and by extension of its wider environment. Laboratory crushers are therefore crucial components for various environmental studies, enabling researchers to extrapolate accurate data about an ecological area with minimal invasiveness.

This article will explore the working principle of a laboratory crusher in more detail:

Laboratory Crusher Working Principle

The primary mechanism of conventional laboratory crushers is the jaw crusher, which typically features a fixed plate and a mechanically-operated, gyrating plate. These are arranged in an angled, funnel shape, with a wider feed opening at the top and a narrow discharge aperture at the bottom. The gyrating plate crushes samples against the fixed plate with a rocking motion that ensures samples are successively crushed towards the discharge point. This process can result in significant wear to the fixed plate as an abrasive material will repeatedly be pressed against its static surface with significant force.

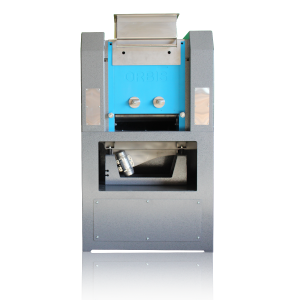

The Orbis OM50 crusher combats this issue with a double-acting jaw crusher design, which features dual-acting top and bottom jaws capable of holding a 10kg sample and crushing a 70mm sample to 2mm in a single pass. It has vastly improved efficiency and is proven to reduce samples by 35 times their original size. This is made possible by gyrating both jaws simultaneously and employing plates of high chrome iron for improved abrasion resistance. A larger model known as the OM100 Crusher uses this same principle to process samples of up to 15kg, reducing samples of 110mm to 2mm in a single pass.

Specialized hydraulic laboratory crushers are designed to trim excess material from, and drill hollow cores into samples before the crushing process begins.

Laboratory crushers are also commonly integrated with additional equipment to allow for automation of procedures or for more tailored specifications. The OM50, for example, combines the double-acting jaw crusher with a rotating sample divider to intuitively separate powdered samples following the crushing process. After the sample is pulverized and transported via a vibratory feed to the RSD module, it is split using either single or duplicate split processes. The OM50 can alternatively be combined with a linear sample divider (LSD) which improves automation of processes by allowing operators to pre-select sample weights and suitable splits for an improved degree of splitting accuracy, with multiple dividing options available for a single pass.

The improved accuracy of these laboratory crushers ensures the production of finely-powdered samples through multiple passes, creating a product that is suitable for the performance of subsequent XRF analysis.

Laboratory Crushers from XRF Scientific

XRF Scientific are experts in the manufacture and supply of specialized laboratory equipment for a broad range of academic and industrial applications. We are dedicated to improving scientific processes across the world by developing and providing intuitive equipment that improves laboratory throughput and accuracy.

Our laboratory crushers are available to a range of specifications. If you would like any more information, please do not hesitate to contact us.