Why use expensive ceramics in XRF sample preparation?

Rob McConnell, Technology Division General Manager, talks about the reason we use ‘expensive’ ceramics in our fusion machines. Rob is a ceramics engineer and has been with XRF Scientific for over 10 years:

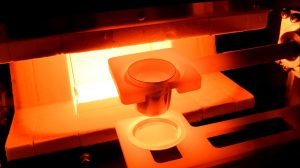

We have been developing electric furnaces for over 20 years now, initially the Modutemp range and more recently the xrFuse range of fusion machines. One of the problems we faced in the past was finding a material to use for the platinum crucible and mould holders that didn’t contaminate the sample. Initially we used Inconel for our fusion furnaces, which worked reasonably well, however over time the material can break down, and contamination can occur with over-use of the holders.

Around 6 years ago we discovered a special high tech ceramic, which proved to work incredibly well at the high temperatures our customers are conducting fusions at. The material is so special that there are only a few manufacturers in the world who can produce the right grade of ceramic required.

We initially rolled the ceramics out in our semi-automatic Modutemp fusion machines at some labs here in Australia. The holders worked very well, and many users have found them lasting up to 5 times longer than the Inconel based holders. Even if the holders are more expensive than those made from Inconel, the economics certainly stack up when you consider the extended life and improved QC.

As with all ceramics, they are brittle in nature, even if they are very strong, and therefore they need to be handled with care. We also recommend customers periodically clean the holders, especially if they have experienced a flux spill from a volatile sample.

Our xrFuse range of machines come completely standard with our high tech ceramic holders at no additional charge, including our entry point machine the xrFuse 1