Platinum mould flatness and its effect on XRF analysis

In XRF techniques the observed fluorescent X-ray counts are not directly proportional to concentration but must be corrected for absorption-enhancement effects caused by the influence of all other elements in the samples. Matrix correction is typically carried out by analyzing all major elements likely to be encountered, using extensive standard suites for all elements and by generating alpha correction factors using fundamental, empirical or regression methods or a combination of these approaches.

During use of this technique, problems can arise with glass disc curvature due to platinum moulds becoming convex over time and variation in XRF cup quality. Both of these factors lead to serious progressive decreases in precision.

In Australia where XRF Scientific’s manufacturing operations are based, the highest number of lithium borate fusions in the world are performed. This closeness to the industry has allowed us to develop a unique understanding of the problems faced on a daily basis by the XRF analysist.

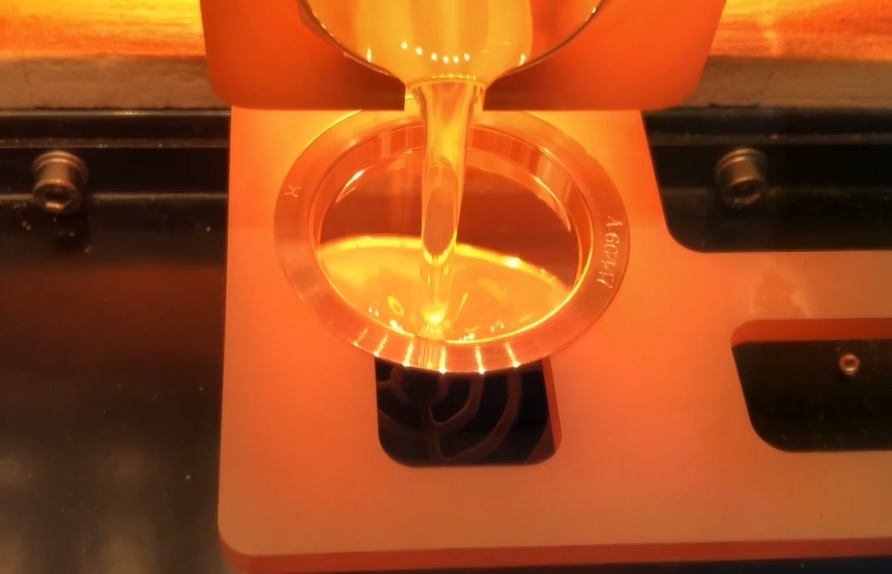

One key area of concern that XRF Scientific has addressed with customers is the flatness of platinum moulds used to cast the melt of the lithium borate flux, in which the sample has been homogenously mixed with. The manufacturing process at our platinum factory in Melbourne has been refined through the last twenty years, to a point where the flatness of our moulds are the industry standard.

Test equipment and quality processes ensure our platinum moulds are consistently flat to our industry leading standards. The platinum melting and fabrication processes employed ensure that our moulds stay as flat as possible over time. In house precious metal refining processes also ensure a high quality platinum gold alloy is provided, and that the platinum mould does not contaminate your sample preparation process.

Pease do not hesitate to contact us to discuss our quality and flatness standards, and how they can reduce your sample preparation errors influencing your x-ray fluorescence (XRF) analysis results.