Search Results for ‘’

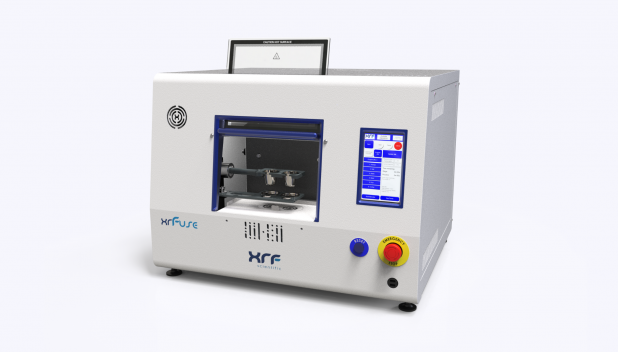

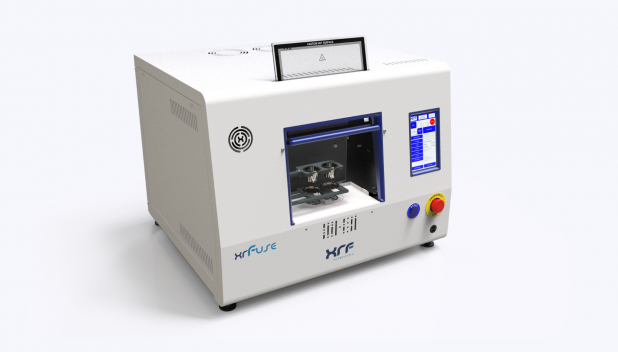

xrFuse 2 (New Release)

Request a Quote

Next generation xrFuse fusion technology has arrived. Featuring absolute process flexibility, higher maximum fusion temperatures, advanced labware cooling and streamlined maintenance.

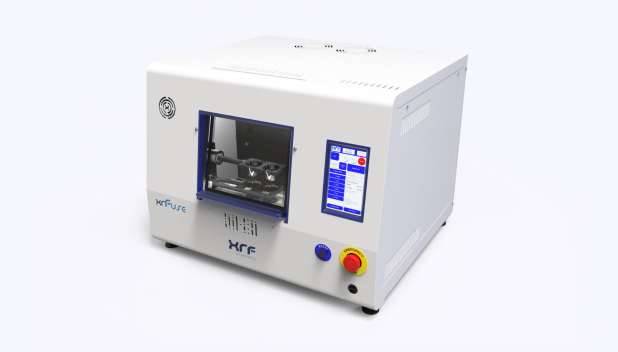

The xrFuse 2 is an instrument that allows for the seamless sample preparation of glass beads for XRF and ICP solutions. The system is a compact machine, ideal for lower throughput users or specialised applications. Through our proprietary quick change-out mechanism, users can alternate between XRF glass bead and ICP solutions preparations in a matter of seconds. The unit is cold-to-cold, fully CE certified, extremely safe and easy to use.

The xrFuse range of automated electric fusion machines has been developed based on more than 25 years of experience of fusion technology and applications. Designed with the latest thermal imaging technology, consumer tested in the biggest XRF laboratories in the world, xrFuse is designed with the customer in mind.

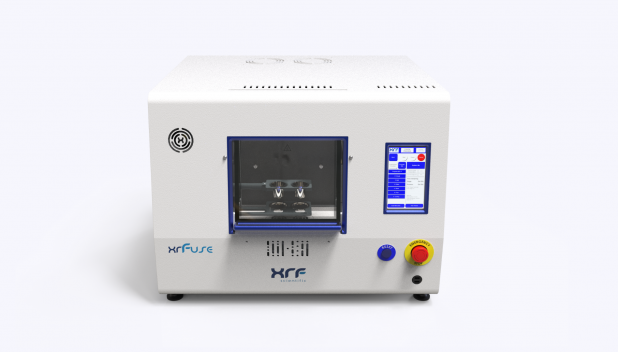

Zero Contamination – The ceramic cradle and holders ensure that the environment for creating beads has zero contamination from these sources.

Reliable and Robust – Designed for maximum uptime in demanding conditions. Includes very few moving parts for reliable operation.

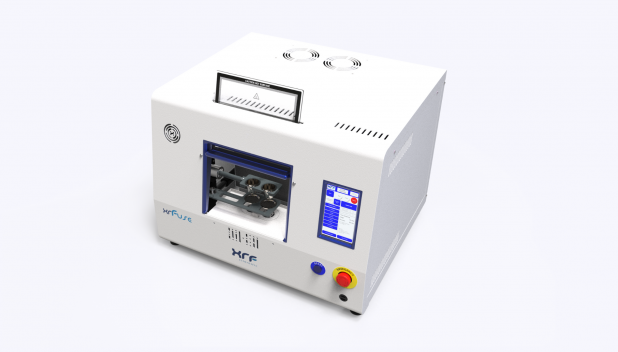

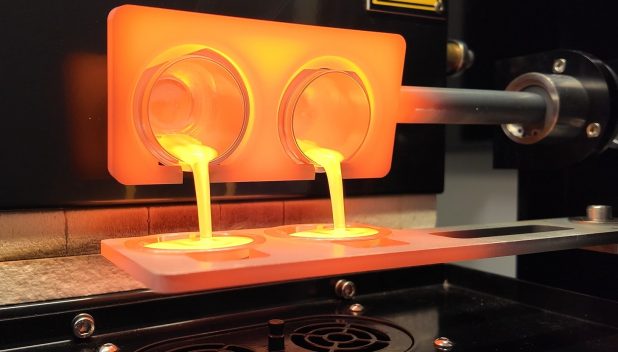

Fast, Precise Heating and Cooling – xrFuse features a highly efficient furnace chamber to reach your fusion temperature fast. Separate cooling of crucibles and moulds allows you to create the perfect glass bead and to cool crucibles to a safe temperature. Cooling inlets are filtered to ensure no external impurities interfere with your samples. Precise temperature control and programmable heating profiles to handle full spectrum of XRF and ICP fusions.

Process Flexibility / ICP – The machine is designed for both flexible pre-heating and ICP processes. Simple to access, control and monitor. All at the touch of a button. The user interface is designed in such a way that it can meet the need for consistency of a production laboratory, while at the same time giving the analytical chemist the flexibility to modify parameters as required.

Safe Operation – All external surfaces are cool to touch. Advanced labware cooling to protect operators. CE certified design.

Built to Last – The xrFuse range has evolved from robust and reliable technology developed for high volume, high up time applications in the Iron Ore industry in Australia. This tough environment has driven the development of machines with robust components with significant lifetimes. When you buy an xrFuse, it’s built to last!

Fusion is a highly versatile method for preparing samples for XRF and ICP analysis. It accommodates all fusion types, including lithium borates, peroxide and alkali fusions, and is compatible with a wide range of crucibles such as zirconium (Zr), nickel (Ni), and platinum (Pt), ensuring reliable, consistent results across diverse sample matrices.

XRF (Borate Fusions)

Iron ore, copper, nickel, aluminium, bauxite, rare earths, manganese, coal ash, tantalum, zinc, lead,

uranium, mineral sands, cement, clinker, ferro alloys, ceramics, catalysts, glass and more.

ICP (Borate and Alkali Fusions)

Refractories, rocks, chromite, resistant alloys, silicates, aluminates, aluminosilicates, zirconium

silicate, barite, titanium oxide, dolomite, limestone, lime and more.

| Maximum temperature | 1300°C |

| Number of sample positions | 2 |

| Throughput | Up to 8 beads per hour |

| Programmable recipes | Up to 100 user-defined recipes with customisable names, plus pre-set programs for common applications. Controlled heating ramp profiles with multiple temperature stages |

| User interface | Touchscreen control with password-protected access levels |

| Adjustable paramaters | Temperature, step duration, agitation speed and angle, pouring angle, cooling airflow, or magnetic stirring |

| Fusion status display | Clear indication of total remaining time and individual step progress |

| Crucible cradle / mould holders | High purity ceramic |

| Voltage | 2 or 3 Phase 200-220V or Single Phase 230-240V in 15A or 20A |

| Crucible | 30g (95% Pt / 5% Au or Fusion Alloy), Zirconium or Nickel |

| Moulds | Available in various sizes (95% Pt / 5% Au or Fusion Alloy) |

| Safety | CE Certified, CSA, ‘Cold to Cold’, CAT 4 rated safety circuit |

| Size and weight | 540mm (H) x 710mm (W) x 680mm (D) – 80kg |

| Fume extraction | Integrated extraction system with exhaust adapter |

| Heating elements | Silicon carbide |

| Connectivity | USB communication link |

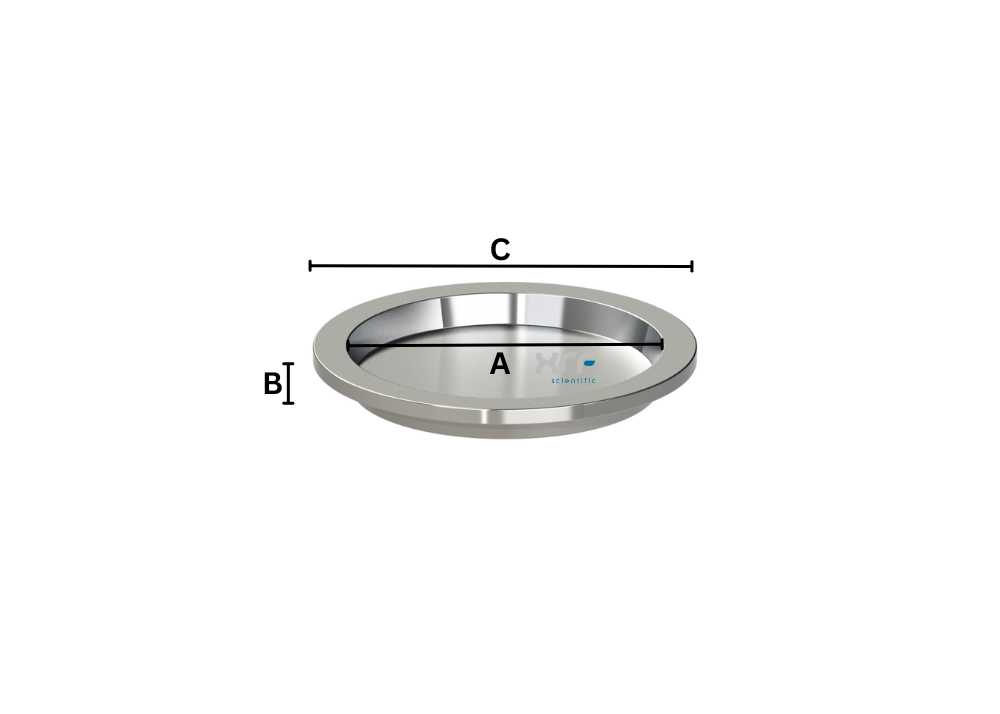

Mould

| Code | A | B | C | Estimated Weight (g) |

|---|---|---|---|---|

| DM1 | 39/41mm | 4mm | 50mm | 60-100 |

| DM2 | 37/39mm | 4mm | 50mm | 60-100 |

| DM5 | 32/34mm | 4mm | 42mm | 60-100 |

| DM6 | 30/32mm | 4mm | 42mm | 60-100 |

xrFuse Platinum Moulds/Casting Dishes are available in 95%Pt/5%Au (platinum/gold) or SFA (Special Fusion Alloy)

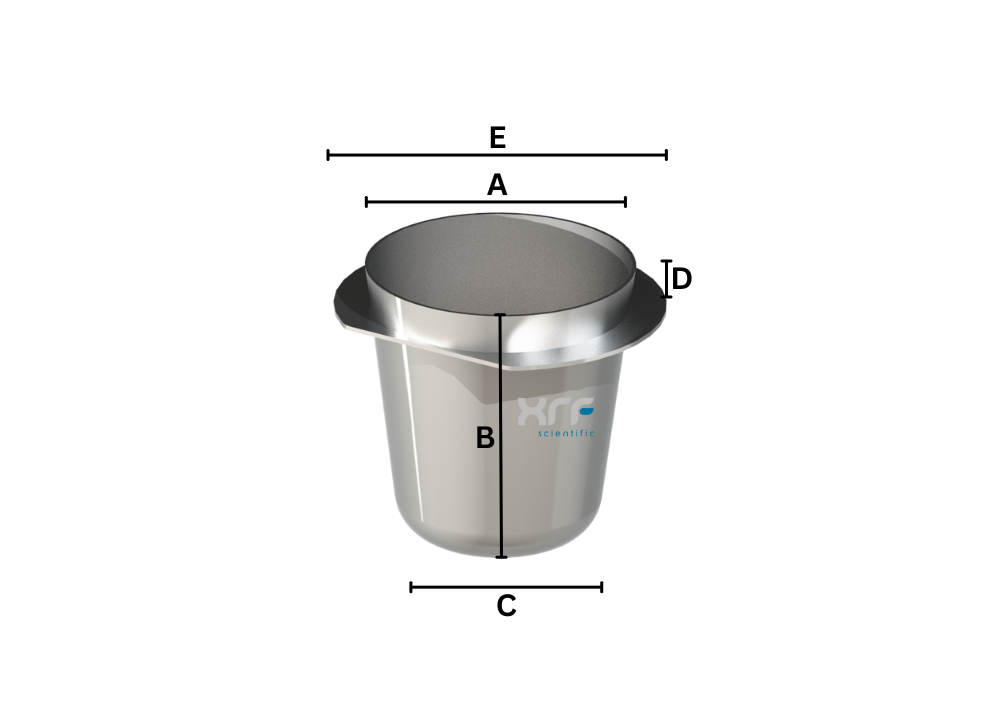

Crucible

| Code | A | B | C | D | E | Estimated Weight (g) |

|---|---|---|---|---|---|---|

| DC1 | 36mm | 35.5mm | 19mm | 6mm | 44mm | 30 |

| DC2 | 36mm | 35.5mm | 19mm | 6mm | 44mm | 40 |

xrFuse Platinum Crucibles are available in 95%Pt/5%Au (platinum/gold) or SFA (Special Fusion Alloy)